- ID Number 19110

- Aug 08, 2023

- 202

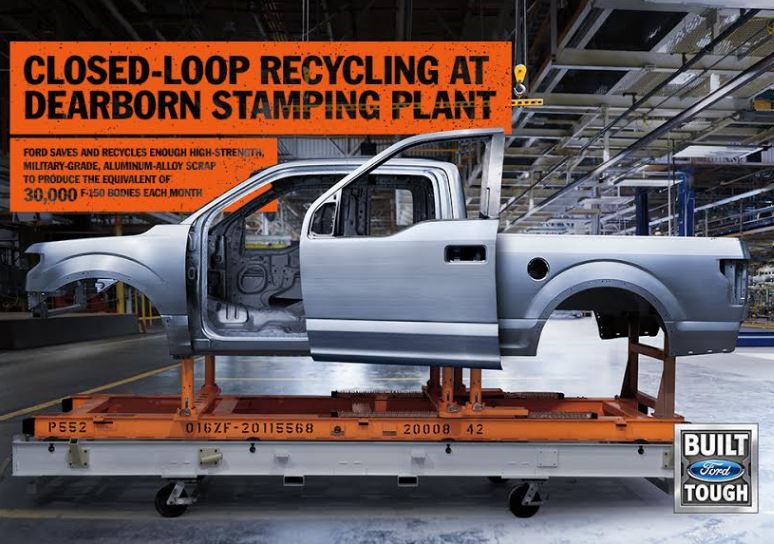

Ford Highlights Sustainability Benefits of Recycling Enough Aluminium to Build 30,000 F-150 Bodies Every Month with Presence at AluSolutions Exhibition

Ford's F-150 is movinged towards the AluSolutions global conference and exhibition in Abu Dhabi tomorrow, showcasing Ford's commitment to sustainability in end-use applications of recycled aluminium. The hardest, smartest, most capable and most safe F-150 ever is also the greenest F-150-- thanks to sophisticated materials like high-strength, military-grade aluminium alloy.

Ford recycles as much as 9 million kilogrammes of aluminium marking scrap monthly utilizing the closed-loop system at Dearborn Stamping Plant, which provides parts to develop F-150 at Ford's Dearborn Truck and Kansas City Assembly Plants.

Selecting aluminium over steel in brand-new vehicle building is the best way to reduce energy usage and carbon emissions, according to Oak Ridge National Lab.

Weight savings from aluminium alloy helps F-150 decrease its life time emissions as compared to the previous steel-body variation. Between 30 percent and 40 percent of a common aluminium coil is developed into scrap in the marking process. This is recycled into new metal for the truck using the closed-loop system.

F-150 SuperCrew and SuperCab with readily available crash caution are the only trucks in their class to earn a Top Safety Pick from the Insurance Institute for Highway Safety. F-150 also is the only full-size, light-duty truck to make National Highway Traffic Safety Administration's highest score, a five-star total vehicle rating and five-star rating for driver and traveler for all crash test designs and cab setups-- SuperCrew, SuperCab and Regular Cab.

The F-150 delivers an impressive mix of power, ability and effectiveness-- from innovative materials that improve resilience and prevent deterioration, to faster processors that improve driving performance, to advancement cargo management and lugging options.

Both the outside and interior design of Ford F-150 reflect decades of listening to clients and understanding their occupational and recreational requirements. The exterior is characterised by a new shape that suggests capability, with a wider Built Ford Tough position, prominent wheel arches and chiselled grille.

Comfort, utility and improvement specify the truck's interior. Ergonomically optimised seating for the front row positions enhances comfort, while extending legroom for rear passengers. Buttons and controls are optimised so they can be operated while using work gloves.

" Recycled aluminium prevents 95 percent of the greenhouse gas emissions associated with main aluminium production. It also uses substantially less energy and water," stated Ziyad Dallalah, Chief Engineer, Ford Middle East, "which is another reason Ford F-150 leads the full-size truck pack in terms of lifetime carbon footprint."

Ford F-150 will be on show at the AluSolutions global conference and exhibit at ADNEC, Abu Dhabi, running May 10-11, 2016. The conference will show how the aluminium market is making continuous enhancements in the ecological efficiency of producing aluminium, in addition to its sustainability benefits in end-use applications-- which is something the F-150 knows a good deal about.

Making History: ASPIRE to Launch Inaugural ‘Abu Dh...

- Apr 23, 2024

ENOC Group partners with Loyyal to enhance ‘YES’ r...

- Apr 23, 2024

Septuagenarian Visitor's Life Saved at Kuwait Hosp...

- Apr 23, 2024